Composite 3D printing is transforming architecture by combining advanced materials with precise additive manufacturing. Here’s a quick look at five standout projects showcasing its potential:

- Mighty Buildings Prefabricated Homes: Uses UV-cured recycled glass composites for fast, waste-efficient housing in California.

- WinSun 5-Story Apartment: Built with fiberglass-reinforced concrete, reducing waste and costs while maintaining strength.

- WASP Tecla Eco-Housing: Sustainable homes made with local clay and natural fibers, cutting emissions and transportation costs.

- IAAC Pedestrian Bridge: Recycled concrete-polymer hybrids form intricate, durable structures in Madrid.

- AIRLAB AirMesh Pavilion: Lightweight yet strong steel-bronze joints create visually striking designs with minimal waste.

Key Benefits:

- Waste Reduction: Up to 95% less waste.

- Cost Savings: Labor costs cut by 80%, project timelines shortened by 70%.

- Sustainability: Materials like recycled glass and natural fibers lower carbon footprints.

Composite 3D printing is reshaping construction, offering faster, cost-effective, and eco-friendly solutions for homes, infrastructure, and more.

3D Printing 3 Ways! Concrete + Metal + Glass!

5 Architectural Projects Using Composite 3D Printing

These projects highlight how composite 3D printing is reshaping architectural construction. Each example showcases inventive materials and design approaches that challenge traditional building methods.

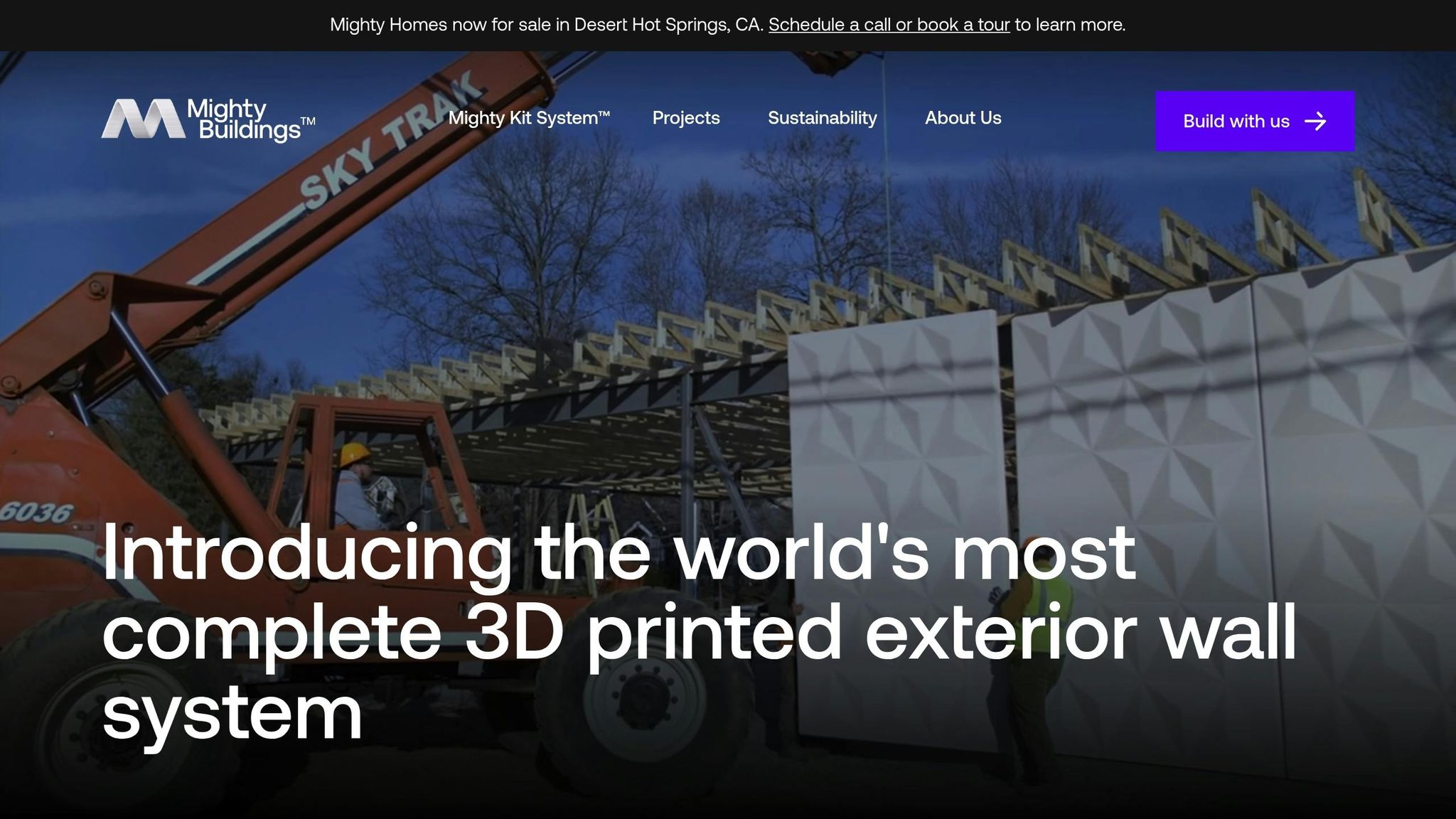

Mighty Buildings' Prefabricated Housing Systems

Mighty Buildings has revolutionized the prefabricated housing market in California by using UV-cured composite materials infused with recycled glass. This approach allows for the creation of modular housing with remarkable speed and precision, significantly reducing construction time compared to conventional methods.

The inclusion of recycled glass in the composite not only strengthens the material but also aligns with sustainability efforts by repurposing waste. This method supports rapid, waste-efficient construction, making it a game-changer in California's competitive housing market, where efficiency and speed are paramount.

WinSun's Multi-Story 3D-Printed Apartment Complex

WinSun captured global attention by building a five-story apartment complex with fiberglass-reinforced concrete using 3D printing. This project proves that composite 3D printing can scale up to handle larger residential structures. The fiberglass reinforcement enhances the tensile strength of the concrete, resulting in a material that outperforms traditional concrete under stress.

By employing fiberglass-reinforced concrete, WinSun minimized waste, eliminated the need for extensive formwork, and reduced costs - all while maintaining structural integrity.

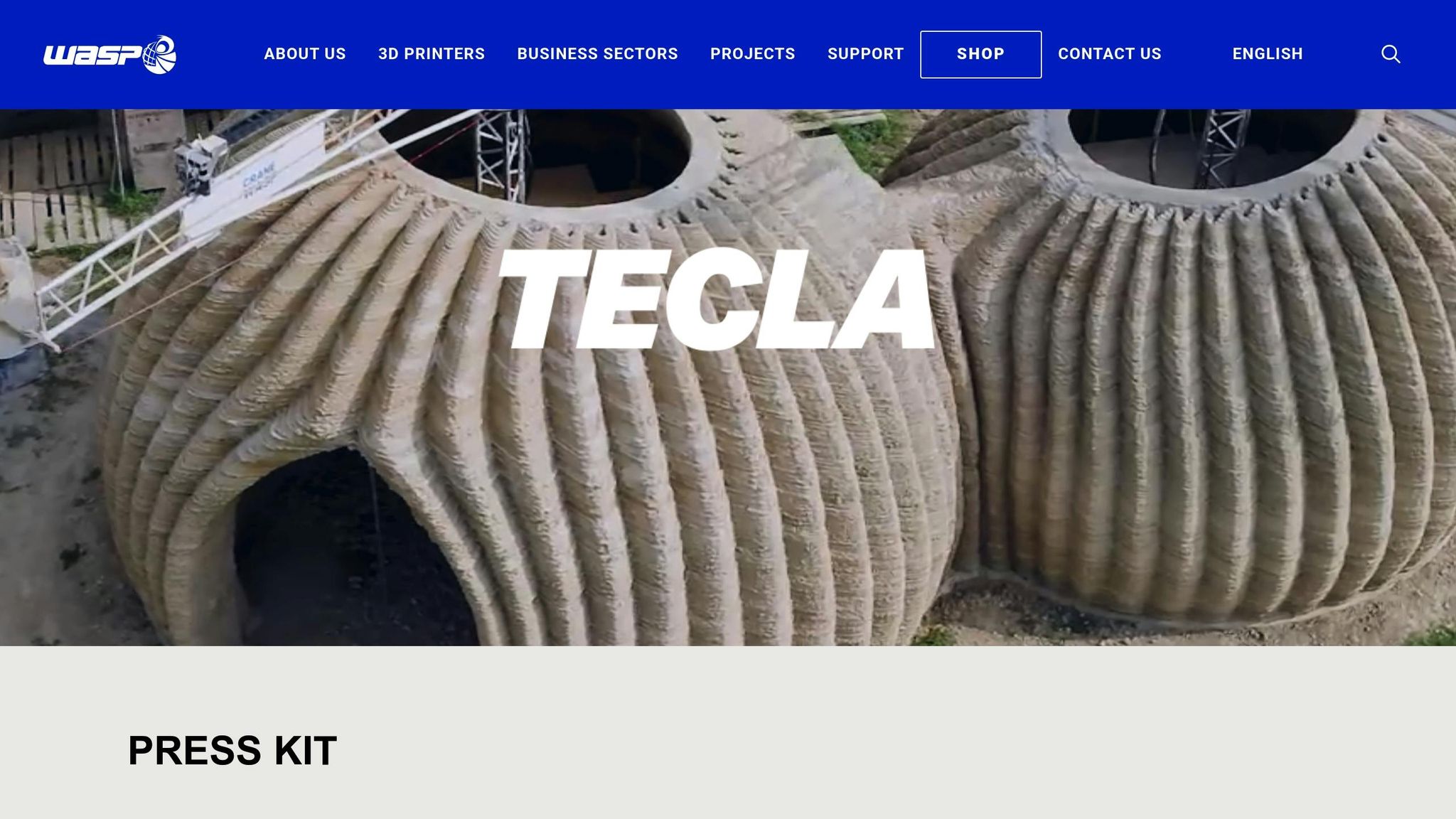

Tecla Eco-Housing Prototype by WASP

WASP's Tecla project is a milestone in sustainable construction, using locally sourced clay and natural fibers to create an eco-friendly housing prototype. This approach reduces transportation costs, lowers carbon emissions, and produces energy-efficient, thermally optimized structures.

The project highlights how composite 3D printing can merge traditional, earth-based materials with modern construction techniques, offering sustainable and durable housing solutions. Its reliance on local materials makes it particularly useful in areas with limited access to conventional building supplies.

IAAC's 3D-Printed Pedestrian Bridge in Madrid

In Madrid, IAAC designed a pedestrian bridge using recycled concrete-polymer hybrids. This composite combines the compressive strength of concrete with the flexibility of polymers. Through precise 3D printing, the bridge achieves intricate, material-efficient geometries while maintaining durability and load-bearing capabilities.

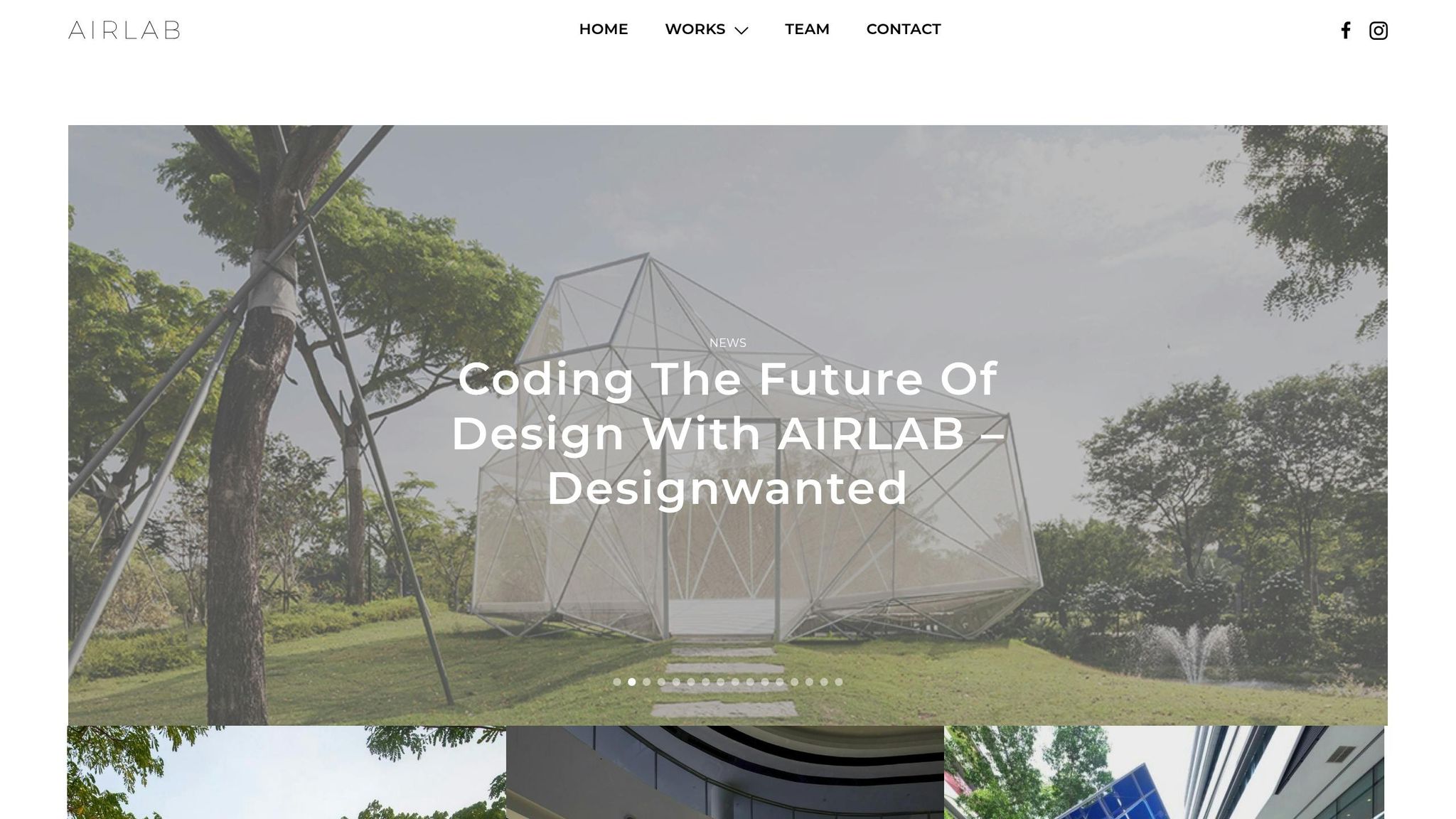

AIRLAB's AirMesh Steel-Bronze Pavilion

The AirMesh pavilion by AIRLAB incorporates 3D-printed joints made from stainless steel and bronze alloys. This combination results in a structure that is lightweight yet strong, with an eye-catching design.

"3D printing reduces labor costs and material waste, making construction more affordable." - Evelyne Hoffman, WINSS

Across these projects, 3D printing has demonstrated the ability to cut labor costs by up to 80% and reduce material waste by 60%, thanks to its precision application methods. Basic structures can be completed in as little as 24 hours, and waste material can be reduced by up to 90%, making it an increasingly appealing solution for sustainable construction.

Together, these examples showcase the potential of composite 3D printing to innovate materials and improve construction efficiency, paving the way for more sustainable and effective building practices.

Comparison of Composite Materials Used

Material Performance Metrics

The selection of composite materials in architectural projects is anything but random - it’s a calculated choice tailored to meet specific performance needs. Each of the five projects highlights how different composites are used to achieve unique goals in modern construction.

WinSun’s fiberglass-reinforced concrete combines compressive strength with improved tensile properties. It brings corrosion resistance and cost savings to the table, though it doesn’t match the rigidity of carbon fiber. Mighty Buildings takes a different route with their UV-cured composite made from recycled glass. This material strikes a balance between sustainability and performance, offering consistent mechanical properties while speeding up production and keeping waste out of landfills. WASP’s clay and natural fiber composite focuses on harmony with the environment. Natural fibers like hemp deliver excellent thermal insulation, though they fall short in absolute strength compared to synthetic options. AIRLAB’s steel-bronze alloy joints, on the other hand, provide a significant strength-to-weight advantage - 10-15% higher than traditional steel alone.

Environmental Impact of Composite 3D Printing

The environmental footprint of these materials varies widely, but 3D printing in construction offers a game-changing potential to cut CO2 emissions by as much as 70%.

Among the projects, WASP’s Tecla stands out as the most eco-friendly. By using locally sourced clay and natural fibers, it minimizes transportation emissions and achieves a 24.6% lower global warming potential compared to traditional methods. Mighty Buildings follows a similarly sustainable path by incorporating recycled glass, which supports waste reduction by repurposing materials that would otherwise end up in landfills.

WinSun’s fiberglass-reinforced concrete presents a mixed environmental picture. While 3D printing reduces construction waste, cement production remains a significant concern, contributing roughly 7% of global CO2 emissions. However, the precision of 3D printing allows for more efficient cement use, potentially lessening its overall impact.

AIRLAB’s steel-bronze composite is the most energy-intensive option, as metal 3D printing can consume 50-100 times more energy than traditional methods. That said, the extended lifespan of these materials - lasting 2-4 times longer than conventional alternatives - may help offset the initial energy costs.

"Markforged printers also don't waste material and energy because they always produce the part that you designed - whereas with other 3D printers, there's a lot of worry involved."

– Ross Bonner, CTO at Transaera

In general, composite 3D printing significantly reduces waste, cutting construction waste by up to 95% and saving around 4.4 pounds of waste per square foot.

sbb-itb-1be9014

Future of Composite 3D Printing in Architecture

New Materials in Development

The evolution of composite materials is pushing the boundaries of what 3D printing can achieve in architecture. Researchers are now crafting advanced polymers with improved mechanical strength, chemical resistance, and thermal stability tailored for architectural use. These breakthroughs aim to make 3D-printed structures tougher and more adaptable to different environments.

Take, for instance, the work at the University of Virginia, where researchers introduced graphene-enhanced concrete in October 2024. This innovative cement-based composite combines graphene, limestone, and LC2, offering a greener alternative to traditional materials. Data from a Life Cycle Assessment shows that this material could lower greenhouse gas emissions by around 31% compared to standard printable concrete.

"The new composite material is a groundbreaking alternative for 3D-printed construction, as it demonstrates superior mechanical performance and produces fewer carbon emissions compared to conventional methods, thereby reducing its environmental footprint."

– Zhangfan Jiang, Postdoctoral Researcher, University of Virginia

Bio-based materials are also gaining traction. In February 2023, a team from DITF and Arburg developed a 3D printing process using cellulose continuous fibers reinforced with a cellulose matrix. This method operates at room temperature, making it energy-efficient. Crystalline cellulose, known for its high specific stiffness (67–137 GPa·cm³/g⁻¹), adds significant strength to these materials.

"The solution-based and energy-efficient manufacturing method developed by the research team can also be used in other composite materials manufacturing processes. It is particularly suitable for processing temperature-sensitive materials that are in high demand, such as natural or cellulose fibers."

– CompositesWorld

Beyond polymers and cellulose, advancements are being made in metal alloys, ceramics, and even smart materials equipped with embedded sensors. These innovations are paving the way for 4D printing applications, where structures can adapt to environmental changes over time.

Potential Applications in Architecture

These cutting-edge materials are unlocking new possibilities across various architectural domains, including high-rise buildings, disaster-relief solutions, urban infrastructure, and marine construction. The construction industry is undergoing a transformation, with 3D printing addressing challenges like extended timelines and high labor costs. In fact, this technology can slash construction time by up to 70% and reduce labor expenses by as much as 80%.

High-rise construction represents one of the most exciting opportunities. As 3D printing technology scales, it could handle larger structural components and entire building systems. The precision offered by robotic arms and advanced printers is already improving construction accuracy and efficiency.

Disaster-resistant structures are another area where composite 3D printing shines. Emergency housing solutions can be rapidly deployed, with designs that incorporate complex geometries impractical for conventional methods. This capability could revolutionize disaster-relief efforts.

Urban infrastructure also stands to gain. The technology enables the creation of intricate curves and unconventional shapes, reshaping cityscapes while addressing housing demands. With embodied carbon emissions accounting for over 60% of a building's total carbon footprint, the environmental benefits of 3D printing become even more critical.

In marine construction, the demand for composite materials is projected to hit $1.5 billion in 2024, signaling opportunities for waterfront and offshore structures. These materials are also finding their way into renewable energy projects, further supporting sustainable building practices.

Alignment with Architecture Helper's Mission

As composite 3D printing reshapes architectural design, tools that analyze and document these advancements are becoming essential. Architecture Helper’s platform, designed to explore and analyze architectural styles, aligns perfectly with this evolving landscape. The ability to catalog and study these innovations in real-time is crucial as architects experiment with the complex geometries and materials enabled by 3D printing.

The platform's instant analysis tools are particularly valuable for architects navigating these new possibilities. Its mix-and-match functionality allows for seamless integration of 3D-printed components with traditional elements, enhancing both design and structural integrity.

With the global 3D printing construction market expected to grow from $190 million in 2021 to $680 million by 2030, Architecture Helper’s library of architectural insights will play a key role in documenting and guiding this transformation. The integration of bio-based polymers and recycling techniques into 3D printing workflows is not only expanding design possibilities but also inspiring a new era of sustainable and imaginative architecture.

Conclusion

Key Insights from the Projects

Looking back at the projects discussed, it's clear that composite 3D printing is shaking up the construction world, from residential homes to intricate installations. Each example highlights how this technology breaks past the barriers of traditional building methods. Take Mighty Buildings, for instance - they’ve shown how prefabricated housing systems made with composite materials can bring sustainability and efficiency to residential construction. Then there’s WinSun, whose five-story apartment block proved that industrial waste and ground construction materials can be repurposed into solid, functional building components.

On a different note, WASP’s Tecla eco-housing prototype stands out for its use of locally sourced clay-based composites, creating structures that blend beautifully with their surroundings. WASP's work at Expo 2025 in Osaka further emphasizes this approach, using soil-based materials to 3D-print elements for a rest facility. Meanwhile, IAAC’s pedestrian bridge in Madrid and AIRLAB’s AirMesh steel-bronze pavilion showcase how composite 3D printing can handle complex geometries that traditional methods would struggle to achieve.

These projects prove that composite 3D printing isn’t just versatile - it thrives across different scales, from emergency housing to highly intricate designs, all while maintaining structural integrity and flexibility in design.

The Role of Composite 3D Printing in Construction

Composite 3D printing is redefining how the construction industry tackles challenges. By cutting project timelines by up to 70%, reducing waste by 60%, and slashing labor costs by as much as 80% through automation, it’s making construction faster, more efficient, and cost-effective.

The numbers back up its growing influence. The global 3D printing construction market, estimated at $53.9 million in 2024, is expected to grow at an eye-popping CAGR of 111.3% through 2030. Dubai’s ambitious plan to have 25% of its buildings constructed with 3D printing by 2030 highlights the increasing trust in the technology’s scalability and reliability.

Call to Action for Architecture Enthusiasts

The fast-paced development of composite 3D printing in architecture is an exciting frontier for both professionals and enthusiasts. As new materials and applications emerge, keeping track of these advancements is essential to understanding their broader impact.

Architecture Helper is here to guide you through this journey. With tools that provide instant analysis of building images and access to a rich library of architectural examples, the platform equips you to explore and appreciate the role of composite 3D printing in shaping modern construction.

Considering that composite 3D printing can address up to 45% of residential construction costs and as much as 80% of expenses in commercial and industrial projects, it’s likely to become a cornerstone in architectural planning. Dive into these innovations with Architecture Helper and take an active role in shaping the built environment of the future.

FAQs

How does composite 3D printing promote sustainability in architecture?

Composite 3D printing is making waves in architecture by slashing material waste and embracing environmentally-conscious materials. Unlike conventional construction methods, this technology uses exactly the amount of material required for each piece, reducing waste by as much as 95%.

What’s more, many of the composite materials used in 3D printing come from recycled or renewable sources, cutting down the need for new, raw materials. By integrating these practices, architects can shrink the environmental footprint of their projects and support global initiatives aimed at reducing carbon emissions in construction.

How does composite 3D printing save time and money in construction projects?

Composite 3D printing offers impressive cost and time efficiencies in construction. By optimizing material usage, it can slash material costs by up to 40% compared to standard practices. On top of that, the automation inherent in 3D printing minimizes the reliance on skilled labor, leading to a noticeable reduction in labor expenses.

When it comes to timelines, 3D printing can accelerate construction by as much as 95% compared to traditional methods. This is made possible by streamlined production processes and the ability to create intricate structures in a single print, cutting out many conventional assembly steps. These benefits position composite 3D printing as a transformative tool for contemporary construction projects.

What materials are commonly used in composite 3D printing for architecture, and what advantages do they offer?

Composite 3D printing in architecture often relies on polymer-matrix composites, which pair a thermoplastic base - such as PLA, ABS, or nylon - with reinforcing fibers like carbon fiber, glass fiber, or Kevlar. This pairing brings together the best of both materials, resulting in components that are stronger, more durable, and better at resisting heat, all while staying lightweight.

Thanks to these qualities, these composites are perfect for building architectural elements that need to endure high stress and challenging conditions. Beyond their performance, the adaptability of composite materials opens the door to creative designs and precise construction, pushing the boundaries of what's possible in modern architecture.